Optimal Design of Robust Compliant Actuators

NSF NRI CMMI - 1830360

Motion of robotic devices is achieved by enabling the movement of its joints by devices called actuators. This National Robotics Initiative (NRI) project is a collaboration between Locomotor Control Systems Laboratory and Neurobionics Lab at University of Michigan, and Robotics, Locomotion, and Control Lab at University of Denver. The project seeks to understand how to design compliant actuators for human-interactive robots that are energy-efficient and safe across a wide variety of tasks and situations. Unlike rigid actuators, compliant actuators can store and release mechanical energy for greater efficiency and absorb shocks for greater safety, which has made them especially popular in wearable robots (i.e., prostheses and exoskeletons). However, the compliant element of the actuator (e.g., a spring between the motor and the robot joint) must be carefully chosen to achieve these benefits, which has restricted previous implementations to specific use cases. The mathematical framework in this project enables design of compliant actuators that change their physical properties to guarantee safety and efficiency as interactions vary from gentle to forceful. Compliant actuators that are robust to a wide range of conditions can be used for many applications, allowing mass production at lower cost. The energy efficiency of these actuators increases the battery range of mobile co-robots and allows the use of smaller, lighter batteries in wearable robots. This work is also significant to the ubiquity of compliant actuator technology for safe, energy-efficient interactions between robots and humans in uncertain real-world situations outside the laboratory.

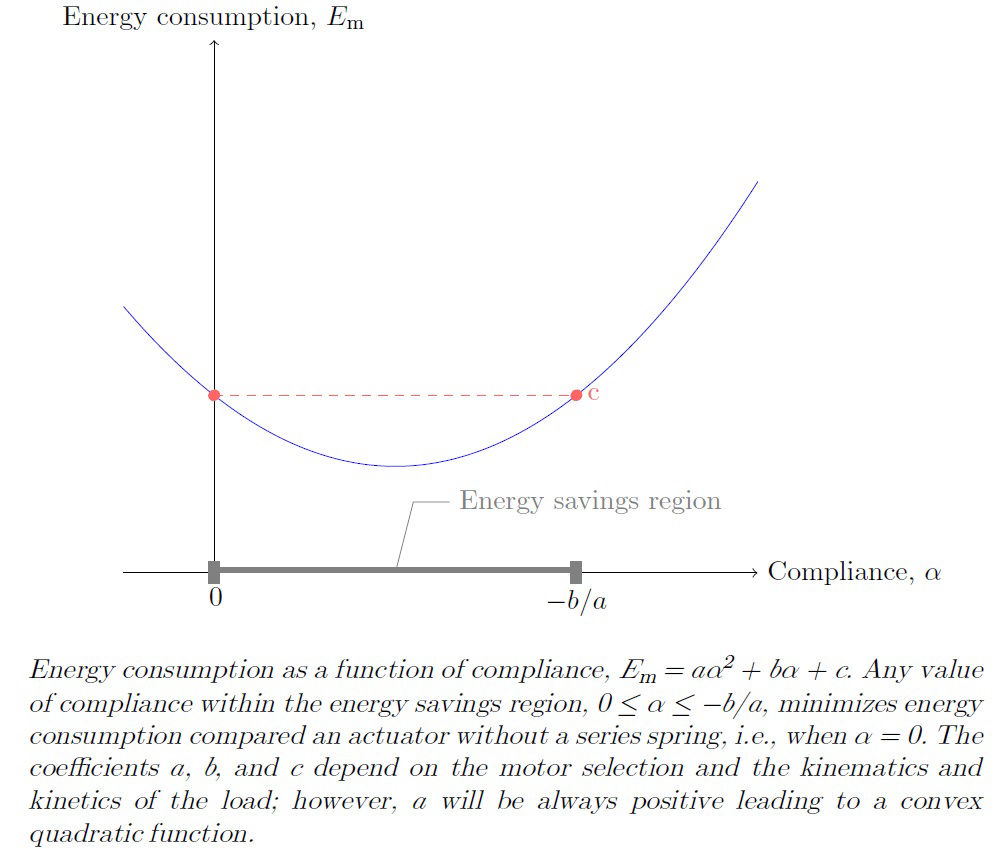

We showed that the energy consumption of a series elastic actuator executing a periodic trajectory is a convex-quadratic function of spring compliance, for linear springs, or a compliance-defection trajectory in the case of nonlinear springs. We also demonstrated that motor speed and torque are affine functions of the spring compliance. As a result, for a given motor selection and periodic trajectory, we formulate series spring compliance as the solution of a convex Quadratically Constrained Quadratic Program (QCQP) to globally minimize energy consumption and satisfy any vector-norm constraint of torque and speed, for example, RMS torque (2-norm) and maximum velocity (1-norm).

In our method, meeting motor velocity and torque requirements is equivalent to satisfying quadratic or second-order cone constraints. The matrices that describe these constraints depend on the task parameters such as load kinematics, kinetics, and modeling assumptions of the motor, which are typically uncertain but bounded in a wearable robotic application. Robust optimization is a popular technique to solve optimization programs that are feasible despite uncertainty in their parameters. However, the sets that define the uncertainty have to be of a specific form. Our research formulates uncertainty sets that lead to computationally tractable solutions that satisfy actuator constraints despite uncertainty in the load torque-speed profiles, precision in manufacturing of the spring, and unmodeled dynamics of the motor.

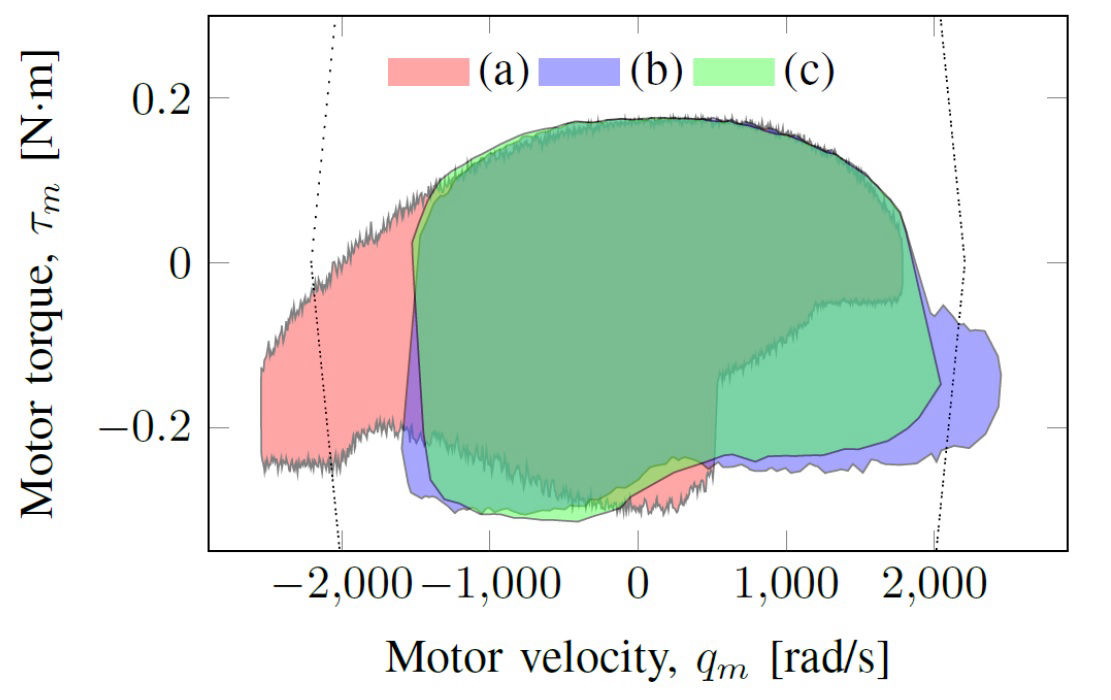

Speed-torque requirements of different SEAs for a powered prosthetic ankle subjected to uncertainty in the load speed-torque profiles, precision in manufacturing of the spring, and unmodeled dynamics of the motor. The region enclosed by the dotted straight lines describes the speeds and torques that satisfy the specifications of a Maxon EC-30 motor. The colored regions describe the expected torque and velocities for the same Maxon motor with (a) no series spring, (b) a series spring with optimal stiffness that neglects uncertainty, and (c) a series spring that satisfies actuator constraints despite uncertainty using our formulation. The robust design (c) is the only actuator that satisfies the actuator constraints for all possible values of uncertainty.

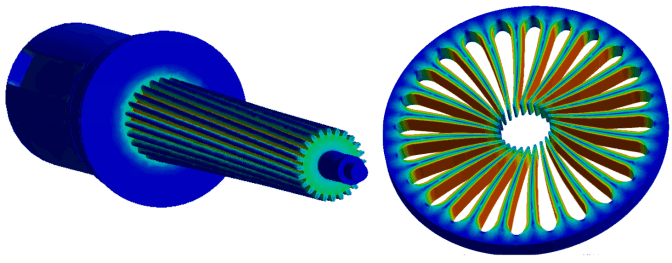

Given the nature of our theory's claims, a proper validation experiment requires a testing apparatus that can track position/torque trajectories with adjustable, nonlinear springs. Our approach extends the Open Source Leg's Selectable Series-Elasticity design, which mates an involute gear-shaft to a collection of spring disks. Each spring disk features an array of inward-pointing flexible beams that engage with the gear teeth to act as a (nearly linear) rotary spring. The amount of series elasticity can be selected by adding or removing spring disks. Our extension aims to re-design the spring disks to allow selection of nonlinear spring behaviors. This is based on two competing effects: when a beam rolls up on the tip of a tooth, the contact force vector tilts towards the radial direction---producing a softening-type nonlinearity; when a beam is initially disengaged from a tooth, the angle where the beam first engages with the tooth marks an abrupt increase in stiffness---a stiffening-type nonlinearity.

The series elastic actuator testbed at the University of Michigan. By rotating continuously forward and back under different speeds and spring load conditions, the testbed can determine the transmission friction and spring rate. The cylindrical object in the middle of the device contains a stack of spring disks.

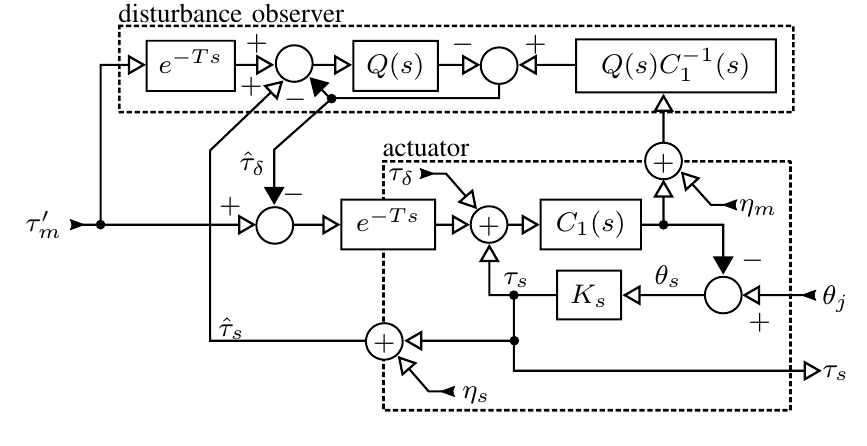

Our spring design framework also extends to springs that serve a torque-measurement purpose in a feedback controller designed to hide the effects of transmission friction in prosthetic legs. This transmission friction is problematic because it prevents a person wearing the powered prosthetic leg from swinging the leg forward under natural pendulum dynamics as they typically do with a passive prosthesis.

But thanks to the spring's ability to measure the output torque, we can use a disturbance estimator---a specialized type of linear feedback controller---to measure and directly compensate for the nonlinear friction effects in the transmission.

The performance we can expect using this strategy ties back to the design of the spring profile because the measurement noise in the deflection sensing is related to torque noise by the marginal spring rate at any particular deflection. Using our optimization methods, we can design springs that optimally trade off the goals of disturbance rejection and energy savings while guaranteeing robust satisfaction of constraints over a range of activities of daily living.

In particular, we hope to exploit stiffening nonlinearity in the spring to attain high torque fidelity at low torques while still satisfying absolute deflection limits at high torques and remaining close to the energy-optimal performance.

We have made all the computer codes assciated with this project publicly available. The shared module on Code Ocean can be easily modified to return the optimal nonlinear series spring for any DC-Motor executing any periodic task. As examples, the module describes the design of an optimal nonlinear spring for and SEA-based prosthetic ankle or knee during level ground walking or running using the motors from the prosthetic legs V1 and V2 built at the LocoLab. The codes and the corresponding guides and descriptions can be accessed here.

Kumar, Saurav and Zwall, Matthew and Bolivar-Nieto, Edgar and Gregg, Robert D. and Gans, Nicholas. "Extremum Seeking Control for Stiffness Auto-Tuning of a Quasi-Passive Ankle Exoskeleton," IEEE Robotics and Automation Letters, v.5, 2020.

Bolivar, Edgar and Rezazadeh, Siavash and Summers, Tyler and Gregg, Robert D.. "Robust Optimal Design of Energy Efficient Series Elastic Actuators: Application to a Powered Prosthetic Ankle," IEEE International Conference on Rehabilitation Robotics, 2019.

Allen, David P. and Bolívar, Edgar and Farmer, Sophie and Voit, Walter and Gregg, Robert D.. "Mechanical Simplification of Variable-Stiffness Actuators Using Dielectric Elastomer Transducers," Actuators, v.8, 2019.

Bolivar Nieto, Edgar Alberto and Rezazadeh, Siavash and Gregg, Robert. "Minimizing Energy Consumption and Peak Power of Series Elastic Actuators: a Convex Optimization Framework for Elastic Element Design," IEEE/ASME Transactions on Mechatronics, 2019.