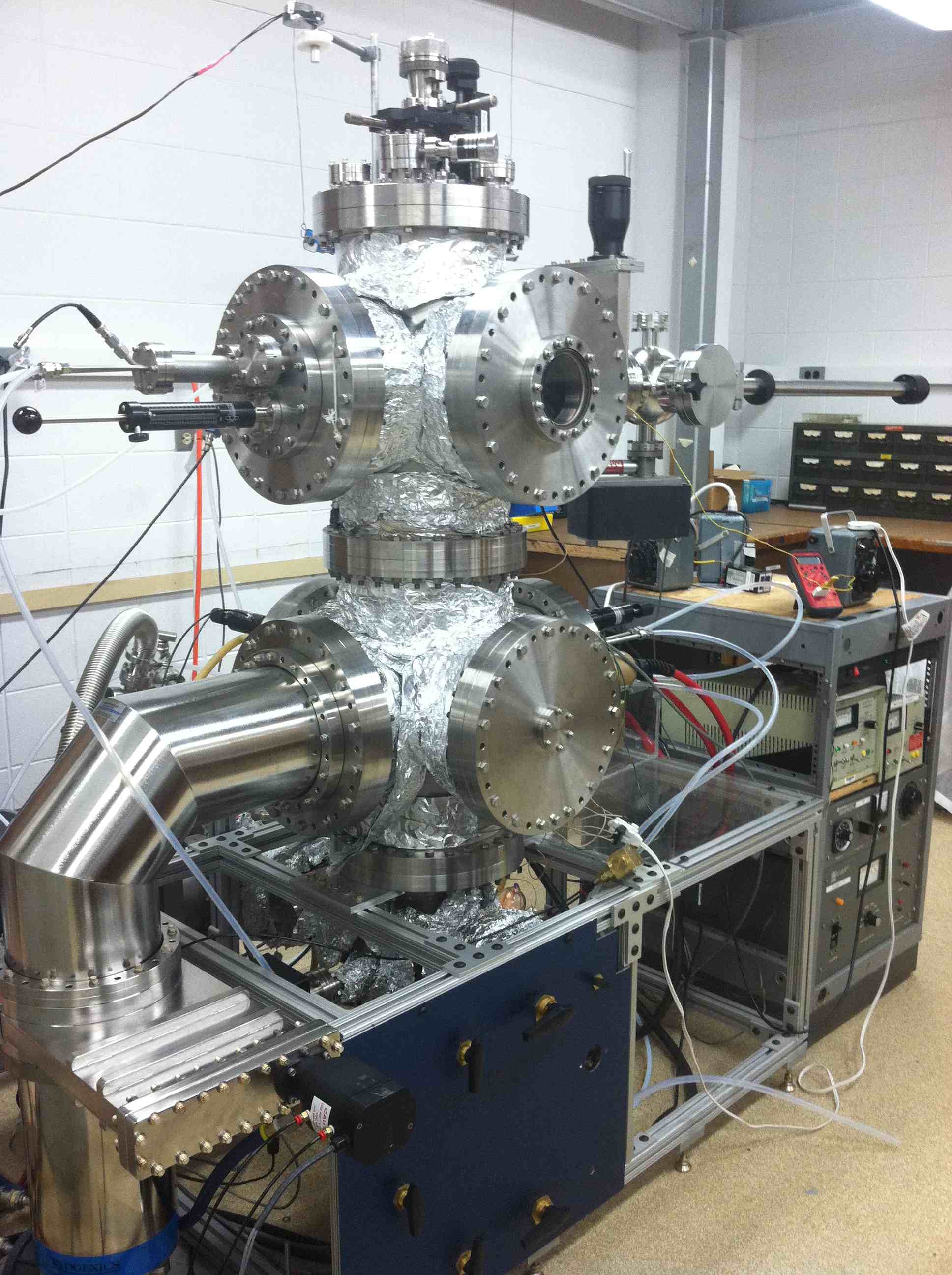

UHV evaporation system (The Thirteener)

A load-locked, cryo- and ion-pumped vacuum system with base pressure of ~10-10 Torr, designed for co-deposition of two materials via thermal and e-beam evaporation. Features relatively long sample-to-source distance with the sample directly above the e-beam pocket for improved reliability in nanoscale liftoff lithography. Substrate size up to a 3" wafer.

Veeco v401 ("she's old, but she'll hold...")

Simple HV thermal evaporation system capable of depositing up to 4 different metals sequentially.

Coming Soon...

Two additional thermal evaporators, and RF sputtering system.

Other Facilities in DU Physics

HV 7-target thin film heterostructure growth system (Fan Research Group)

A cryopumped, load-locked HV system with seven installed 2" sputter guns allows co-sputtering of up to four targets simultaneously in Ar or O2 gas. The substrate can be RF biased and also heated to 850o C. The chamber is also equipped with an ion milling source for performing dry etching, which will be essential for varying the nature of interfaces and improving charge and spin transport between metal layers in NLSVs and other structures (above: Prof Fan and URA during system installation).